East-West Metro is like no other Metro line in the country as it posed engineers challenges they rarely encountered before.

The unusual challenges — an ancient river, its very soft soil and ageing edifices overground, to name only a few — demanded a unique approach.

Deploying tunnel-boring machines (TBMs) that would close like a submarine if water started seeping from above, using soil-boring machines that could go very deep to collect samples from the riverbed and burrow through clay — engineers who were involved in the construction of the country’s first underwater Metro tunnel explained to this newspaper a day after the formal launch of the stretch the uniqueness of the project and the challenges they faced.

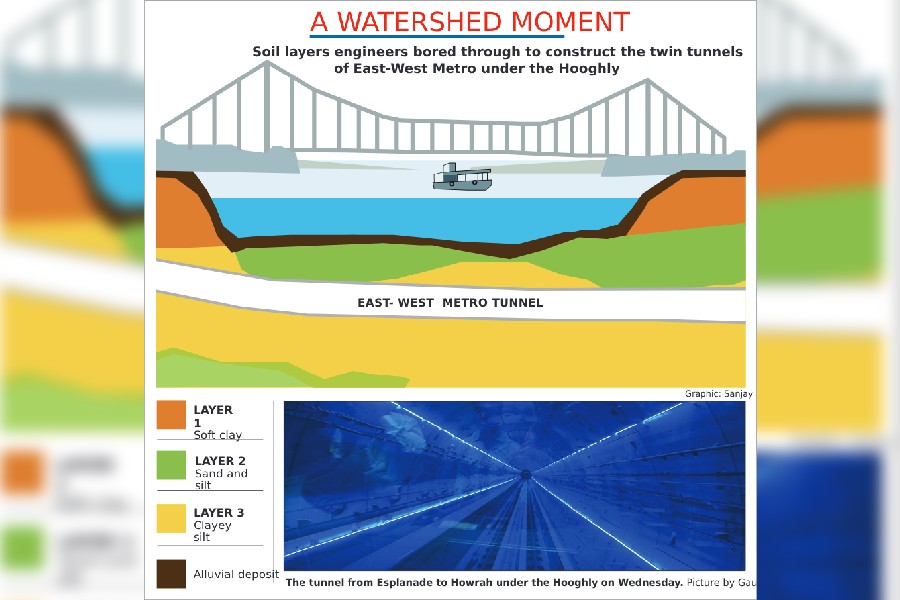

The boring of the 500m-long tunnel under the Hooghly — which is part of the Esplanade-Howrah Maidan stretch of East-West Metro that Prime Minister Narendra Modi formally inaugurated on Wednesday — took two months and five days in 2017.

The Telegraph spoke to engineers who were involved in the project and tunnel-boring experts to learn about some of the unique features of the underwater stretch.

‘Submarine’

The two machines that burrowed the two tunnels under the Hooghly were equipped with technology that allowed them to shut down like a submarine if there was water seepage from above, engineers said.

“The TBMs were designed in a way that water could not enter from any side. These were German machines and specially designed for underwater tunnel boring,” said Virinder Kaul, vice-president, Afcons Infrastructure, the company that was awarded the contract to bore the tunnels.

Kaul was the project manage in charge of tunnel boring between Howrah Maidan and Esplanade.

“There were three possible inlets from where water could seep in,” Kaul said. One was the screw conveyer inside the TBM, in the front part of the machine. The second was the hyperbolic chamber that gave access to the front blade of the machine and the third was the tail shield.

“These parts of the machine were equipped with special gadgets which would function like shields to prevent water from entering the machine. These would close within seconds of water seepage, allowing the personnel inside to evacuate safely,” said Kaul, who is now overseeing the construction an underground stretch of Delhi Metro.

“Water seepage was the biggest concern for us. Throughout the day, as work progressed, we would check for water seepage because of the river above. Thankfully, nothing untoward happened.”

One TBM at a time

Only one machine was operated at a time under the Hooghly, unlike other underground sections of East-West Metro where both tunnel-boring machines — one for each tunnel — worked simultaneously.

“If there was a snag and we needed spares, those had to be brought from somewhere else. But we could not leave the TBM idle under the water for long for safety reasons,” said Kaul.

“We kept one of the two TBMs on standby outside the stretch under the river, so spares could be taken from it, if needed. Fortunately, there was no such need,” said Kaul.

Soil collection

Collecting soil samples from the riverbed was among the most challenging tasks.

“On the ground, it is easier to collect soil samples using drilling machines because the surface is stable. But on the Hooghly, we had to use barges and move from one portion of the river to another to collect samples. We had to use soil-boring machines, which would go deep into the water and then 30m into the riverbed to collect soil samples,” said Sanniv Banerjee, a structural engineer who was part of the tunnel-boring project.

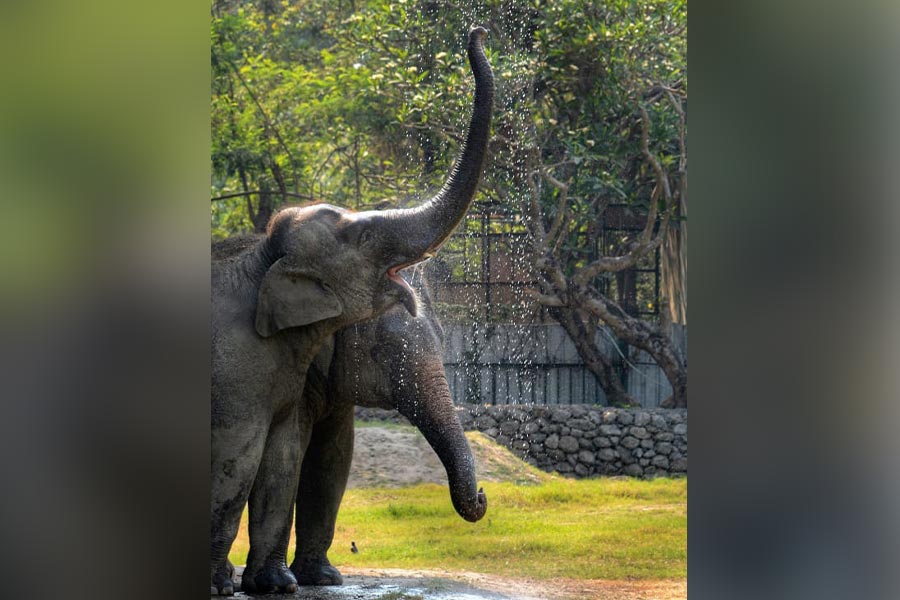

Stiff clay

The engineers said there were layers of different types of soil under the Hooghly, from alluvial to sand and then stiff clay. The tunnel was under 13 metres of soil, consisting of multiple layers, which was under 13 metres of water.

“The tunnel was burrowed through a layer of stiff clay. Because of the nature of the soil, it was easier to drill. Once the machines left the river and entered the banks and the city of Kolkata, it was a mixture of sand and clay,” said Banerjee.

“Stiff clay contains less water and is easier to drill. But sand contains water, making it difficult for the machine to bore,” he said.

Lighter load

Banerjee said the load on the tunnels under the river is lighter than the load on the tunnels in other sections of the East-West Metro corridor.

“There is 13 metres of water, which is lighter than soil of similar volume. So the load on the tunnel in the river segment is less compared to other stretches of East-West Metro,” said Banerjee.